What Is the Science Behind Dry Ice Sublimation?

Dry ice is a fascinating substance that has captured the attention of scientists, industries, and hobbyists alike. Unlike regular ice, dry ice does not melt into a liquid; instead, it transforms directly from a solid into gas through a process known as sublimation. This unique property makes it ideal for cooling, preservation, and special effects.

Understanding the science behind dry ice sublimation is essential for safely and effectively using it in various applications. By exploring the physical principles, environmental influences, and practical applications, we can appreciate why dry ice behaves the way it does and how to harness its unique properties.

This article delves into the science of dry ice sublimation, explaining the physical mechanisms, energy dynamics, and real-world uses, while also addressing safety considerations and common misconceptions.

Understanding Sublimation

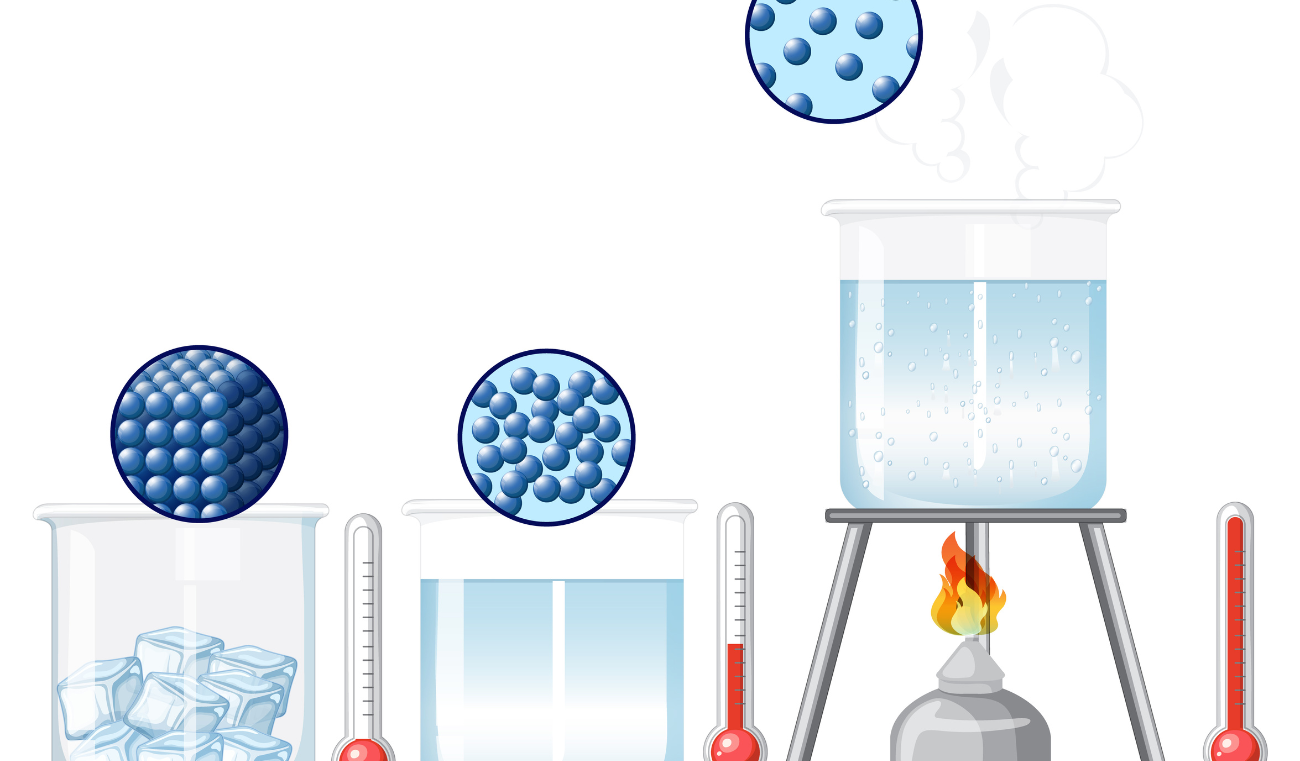

Sublimation is the process in which a substance transitions directly from a solid state to a gaseous state without passing through the liquid phase. For dry ice, this means it turns from solid carbon dioxide (CO₂) into CO₂ gas when exposed to normal atmospheric conditions. Unlike water ice, which melts into liquid water before evaporating, dry ice skips the liquid phase entirely.

This phenomenon occurs because of the unique physical properties of CO₂. At pressures and temperatures commonly found at sea level, CO₂ cannot exist as a liquid. Instead, it sublimates at –78.5°C (–109.3°F). The gas released from sublimation is cold and denser than air, which contributes to the fog effect often seen in demonstrations and theatrical uses.

Sublimation also explains why dry ice is ideal for cooling. As it absorbs heat from its surroundings to transition into gas, it effectively removes energy from nearby objects, lowering their temperature without leaving a liquid residue. This process underpins the many industrial, medical, and entertainment applications of dry ice.

Physical Properties of Dry Ice

Dry ice is solid carbon dioxide with several distinctive physical properties that make sublimation possible and useful. It maintains an extremely low temperature of –78.5°C (–109.3°F) and is much denser than atmospheric air. Its solid form is typically available as blocks, pellets, or sheets, each designed for specific applications.

The low temperature of dry ice allows it to absorb large amounts of heat from its surroundings during sublimation. This heat absorption is what makes it effective for cooling and preservation. Additionally, because it transitions directly into gas without forming a liquid, dry ice does not cause water damage or create excess moisture, a significant advantage over regular ice.

Carbon dioxide’s unique molecular structure contributes to these properties. Under standard atmospheric pressure, CO₂ sublimates rather than melting, meaning it bypasses the liquid state entirely. This combination of extreme cold, direct sublimation, and clean phase transition makes dry ice an efficient and versatile cooling solution for food transport, scientific experiments, and theatrical effects.

The Role of Temperature and Pressure

Temperature and pressure are critical factors that influence the rate of dry ice sublimation. Dry ice sublimates faster in warmer environments because heat energy accelerates the transition from solid to gas. Conversely, lower temperatures slow the process, extending the duration of its cooling effect.

Pressure also plays a significant role. At standard atmospheric pressure, dry ice cannot exist as a liquid and will always sublimate. However, increasing pressure in a controlled environment can temporarily alter the sublimation rate, although this is generally only relevant in industrial or laboratory settings. Understanding these environmental influences is crucial for effective use, whether for shipping perishable goods, preserving scientific samples, or creating visual effects.

By carefully controlling temperature and exposure, users can maximize dry ice efficiency, ensuring that it provides consistent cooling over the intended period. Improper handling or neglecting environmental conditions can lead to faster sublimation, reducing effectiveness and potentially creating safety hazards.

Energy Transfer in Sublimation

The process of sublimation involves significant energy transfer. As dry ice absorbs heat from its surroundings, this energy is used to break the molecular bonds holding the solid CO₂ together, allowing it to transition into gas. This absorption of heat results in a cooling effect, which is why dry ice is so effective at preserving perishable items or creating chilling effects in events and experiments.

The energy transfer is measured as latent heat of sublimation, which is higher than the heat required to melt regular ice. This means that dry ice can absorb more energy before completing the phase change, making it a highly efficient cooling agent. Unlike water ice, it does not produce liquid water, which can cause mess or water damage during storage or transport.

This principle underpins the wide range of applications for dry ice, from industrial shipping and laboratory storage to entertainment and culinary uses. Understanding energy transfer in sublimation helps users optimize dry ice placement, insulation, and handling for maximum efficiency.

Applications Leveraging Sublimation

The sublimation property of dry ice makes it an invaluable tool across various industries. In the food and beverage sector, dry ice keeps perishable items frozen during shipping without the mess of water from melting ice. It is particularly useful for long-distance deliveries of seafood, dairy, or frozen meals, maintaining consistent low temperatures.

In medical and laboratory settings, dry ice sublimation ensures that biological samples, vaccines, and reagents remain at ultra-low temperatures. Its predictable cooling behavior allows researchers and healthcare professionals to safely store and transport temperature-sensitive materials.

Dry ice is also popular in the entertainment industry. The fog effect created when dry ice sublimates in water adds dramatic visual elements to concerts, theater productions, and parties. Culinary professionals use dry ice for presentation and preservation, chilling dishes or beverages instantly without adding liquid.

This range of applications demonstrates how the science of sublimation translates into practical benefits, combining efficiency, cleanliness, and versatility in multiple fields.

Safety Considerations During Sublimation

While dry ice offers many benefits, its sublimation process requires careful handling. Because it turns directly into carbon dioxide gas, excessive accumulation in enclosed spaces can reduce oxygen levels and pose an asphyxiation hazard. Adequate ventilation is essential when using dry ice in shipping, storage, or events.

Direct contact with dry ice can cause frostbite due to its extremely low temperature. Always use insulated gloves or tongs when handling sheets, pellets, or blocks to prevent injury. Additionally, storing dry ice in airtight containers is dangerous, as the sublimation gas can build pressure and potentially cause containers to burst.

Following proper safety protocols ensures that dry ice sublimation can be harnessed effectively without risk. Awareness of ventilation, protective gear, and storage requirements is essential for both industrial and personal use.

Myths and Misconceptions

Several misconceptions surround dry ice and its sublimation process. One common myth is that dry ice “melts” like regular ice. In reality, it sublimates directly into carbon dioxide gas without becoming liquid, which is why it leaves no wet residue.

Another misconception is that dry ice is inherently dangerous in all contexts. While improper handling can be hazardous, following safety guidelines—using gloves, proper ventilation, and secure storage—makes dry ice safe for a wide range of applications.

Some also believe dry ice can freeze anything instantly. While it is extremely cold, the actual cooling effect depends on contact time, insulation, and the thermal properties of the items being cooled. Understanding these nuances allows users to use dry ice more effectively and safely, avoiding overestimation of its capabilities.

Clarifying these myths ensures safe and efficient use, demonstrating that dry ice is not only fascinating but also practical when handled correctly.

Conclusion

The science behind dry ice sublimation reveals why it is a unique and versatile cooling solution. By transitioning directly from solid to gas, dry ice provides efficient cooling without leaving liquid residue. Its properties, energy transfer mechanisms, and predictable behavior make it valuable for industries ranging from food and medical storage to entertainment and scientific research.

Understanding the environmental factors, proper handling, and common misconceptions allows users to maximize the benefits of dry ice while ensuring safety. Whether for shipping, laboratory work, or special effects, the principles of sublimation make dry ice an indispensable tool in modern applications.